FABCO Machine Corp has provided NE Arkansas with the highest quality manufacturing and machining services since 1994. We continue to grow thanks to our customers’ support and the demands of an ever-changing manufacturing world. Now with 100,000 square feet of manufacturing floor space and multiple high bays, we have the capacity for almost any project.

Learn More

There are many who subscribe to the convention that service is a business cost, but we view superior service as an investment that can help drive business growth. Investing in quality talent, and ensuring we have the skills, training and tools that enables our team to empathize and actively listen to customers. These tenants are central to our ability to provide consistently excellent service experiences.

Pairing this customer focus with our “We can and will do anything for a customer” attitude and almost anything is possible for your project. Recently, a customer came to us after exhausting other far-flung fabrication shops to have a complicated sheet metal part broke from a special high strength very low elongation material. When the Amada tooling engineers said it was “utterly impossible,” we relayed this to the customer along with the offer to work through the issue alongside the customer if they wished. They did. Over the next few days, FABCO developed alternative methods to accomplish the job and produced samples for lab testing. Over the next weeks FABCO produced almost 400 parts for field testing. This allowed a multi-million dollar product application to proceed.

We take it as a challenge when faced with difficult tasks; innovation is second nature to us.

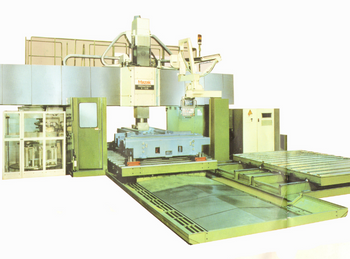

Now with over 100,000 square feet of manufacturing floor space and multiple high bays, we have the capacity for most any project. We continue to upgrade equipment, as well as the skills of our machinists and fabricators. Special emphasis is currently focusing on developing the areas largest and heaviest fabrication facility. Turning work up to 82” diameter can be completed on one of our 4 Mazak Megaturns in one set-up, including all holes and milling operations. With vertical and horizontal milling heads coupled with full C-axis, our Megaturns greatly reduce lead times on complicated and heavy mill/turn jobs. Three MAZAK Five Side twin pallet machining centers allow us to process large work pieces up to 240” x 100” x 60” with a single set-up, ensuring more precise work in heavy machining. This “done in one” approach allows precision that can not be achieved in multiple set-ups.

Recently the Fabco team exceeded my expectations delivering a very large machine part integral to the facility’s production. At my last employer I had used Fabco for 15 years primarily for small die work and progressively larger jobs as their capacity increased. So when a large spindle for a machine failed, I knew who to call.

Maintenance Supervisor

FABCO Machine Company has been doing precision work for Nucor Yamato Steel because their shop has machinery that can do any job that we need. Their passion, skills, and competitive prices allow jobs to be manufactured professionally and timely as required. They do a large amount of work for our steel mill that employs close to 1,000 people and produces around 2 million tons of structural steel yearly. If you look at their job site, I am sure you will be impressed with the machines in their shop. Mr. Bob Clark is the owner, and I, personally, believe he is a man of strong integrity and takes ownership of every job that comes from his shop. I would encourage and recommend FABCO as an extension to any commercial facility.

Roll Shop Manager (Retired)

Biggest machine shop that I have ever been in. All I can say is AWESOME!!!!!

I would encourage and recommend FABCO as an extension to any commercial facility.

Roll Shop Manager(Retired)

”Great people that know what they’re doing and are eager to help!”

”Bob, I cannot praise you and your crew enough!”

Day Support Mechanical, Nucor Coatings Corp