Amada's HG2204 CNC press brake is an ultra-high precision bending solution providing us the ultimate in bending control and accuracy. Six axis backgauge allows the most complicated parts to be processed. Not only can parts be bent to any angle, but through step-bending, almost any radius can be produced. One part programs are developed to produce the desired part and the CNC control can repeat the operation exactly. The CNC operator makes adjustments and allowances for material lot variations. Programs can be taught directly, programmed at the control, or through our RADAN CAM package. Bend indicators can be programmed to come in under program control, measure, and adjust angle.

The addition of our Mazal Integrex E650 takes us to the next level. It has a 10" hole through the spindle and a 3-bar long boring bar stocker which allows it to load 40" long boring bars directly to the ram for maximum rigidity. In addition to big bore options, this machine also has a 42.5" swing option. At 4 meters, it is not our longest Integrex, it is the most capable. The Y-axis has 26" of travel and the B-axis has continuous contouring, capable of hobbing. The Mazak's "done-in-one' capability completes all operations in a single setup - turning, milling, boring, drilling, and more. This machine delivers precision and performance for heavy, large-diameter shaft-type workpieces with a wide range of industry applications.

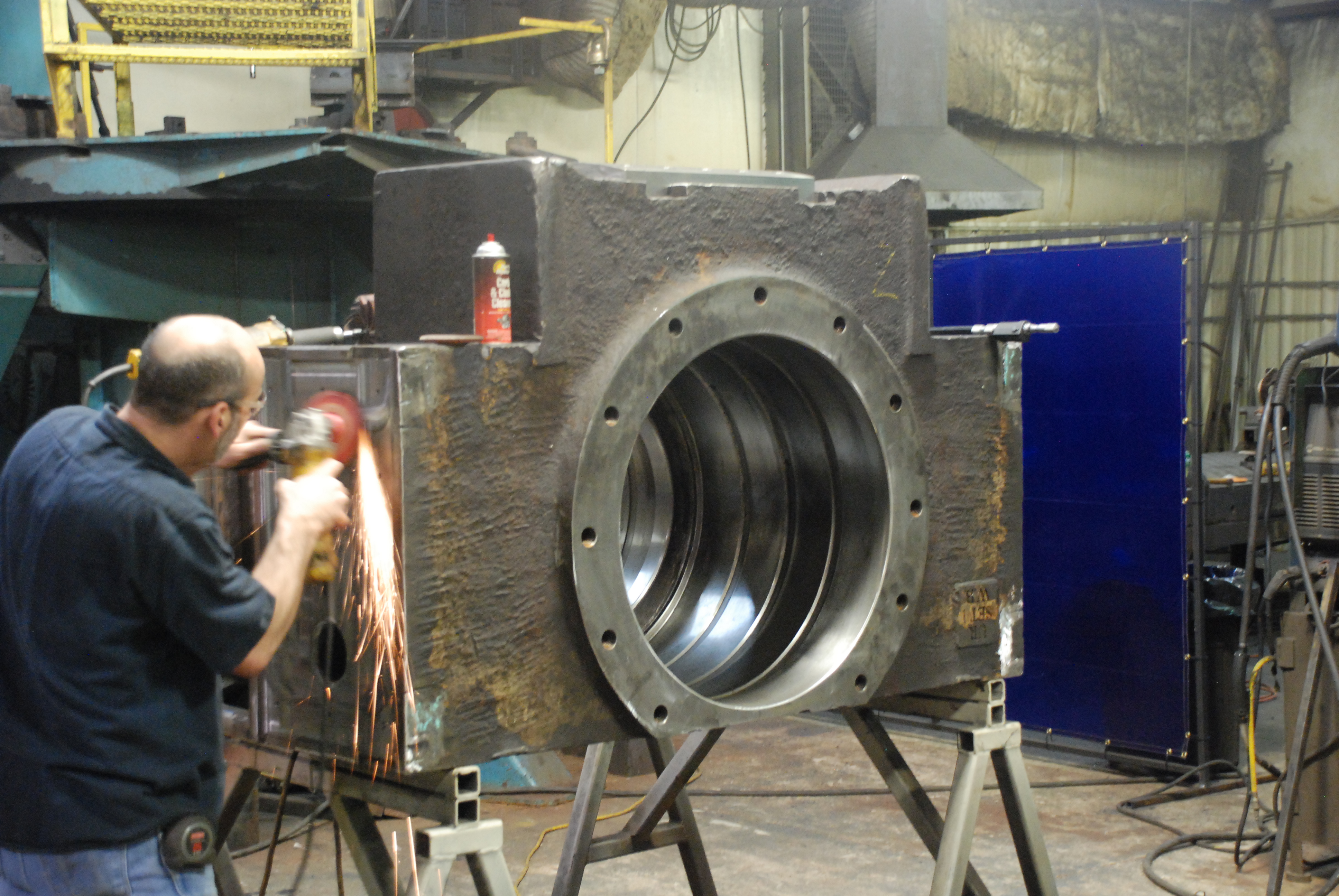

FABCO Machine and Engineering is a resourceful, well-managed company that accepts only the finest work from highly trained, skilled machinists and fabricators. Our customers appreciate our personalized service, comprehensive equipment inventory, and reverse engineering capabilities. We've earned their business and now we want to earn yours!

In our quest to be the best value provider to our customers, we strive to add value to every interaction. Often to our customer do not realize all the service we provide them. Many things we are not line item on a quote or contract, they just need to done so the customer can reap the maximum benift of our partnership.

FABCO has several portable machine in our arsenal to support machine at your facility. At the right is one of two portable mills. These where specially design to recondition existing roll centers that have been worn and damaged over time thus restoring the accuracy of the centers up to 24" diameter. They can be used for placing new center holes as well as other end operations.

FABCO has several portable machine in our arsenal to support machine at your facility. At the right is one of two portable mills. These where specially design to recondition existing roll centers that have been worn and damaged over time thus restoring the accuracy of the centers up to 24" diameter. They can be used for placing new center holes as well as other end operations.

Below (right) is your climax lathe and will the end of the shaft up to 11.25" and 22" long. Also in our arsonal is completely outfitted Climax line boring/welding machine. We also have 12' portable mill and three portable key as well as much more on-site equipment including all manner of welding capabilities

As one of the providers Meta-Lax vibratory stress relief in Arkansas, FABCO is your best choice for stress relief precision metal parts. Or welding technicians are AWS-certified and have years experience with machining stress relief complicated and large part. We are use Meta-Lax@ for post welding stress relief because it offers combination of value, efficiency and innovation our client desire.

As one of the providers Meta-Lax vibratory stress relief in Arkansas, FABCO is your best choice for stress relief precision metal parts. Or welding technicians are AWS-certified and have years experience with machining stress relief complicated and large part. We are use Meta-Lax@ for post welding stress relief because it offers combination of value, efficiency and innovation our client desire.