FABCO Machine Corp provides the highest quality manufacturing and machining services in Northeast Arkansas since 1994. We continue to grow thanks to our customers’ support and the demands of an ever-changing manufacturing world. Now with 100,000 square feet of manufacturing floor space and multiple high bays, we have the capacity for almost any project. We continue to upgrade equipment, as well as the skills of our machinists and fabricators. Our special emphasis is currently focusing on developing the area's largest and heaviest fabrication facility. Our Engineering department uses state-of-the-art CAD/CAM software and can help with initial design, analysis, and build management. We develop 3D models in-house for our CNC programs for our 54 CNC machines and can operate directly from your models.

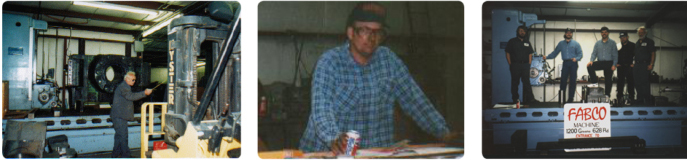

FABCO Machine and Engineering is a family-owned and family-oriented business, blessed by God, to have been growing for over 25 years. Bob Clark began this business in 1994 with the help of his father, Bob Sr. and friend Trent Dowler (both pictured below along with Jim Huddleston, the first employee, Aven Hodges, and Wayne Crossno) with no idea what God had in store for the future of FABCO. Today, the second generation is represented with Robert and Jay Clark following in their elders footsteps going on towards new and bigger challenges. The real story, however, is the rest of the FABCO family! Some of whom have been working hard and steady for the last 20 plus years and all of whom are dedicated to providing our customers with the best value possible. They are the secret of our success!

There are many who subscribe to the convention that service is a business cost, but superior service is an investment that drives business growth. We prioritize investing in quality talent to ensuring our customers have the skills, training, and tools available in the FABCO team to consistently provide excellent service experiences.

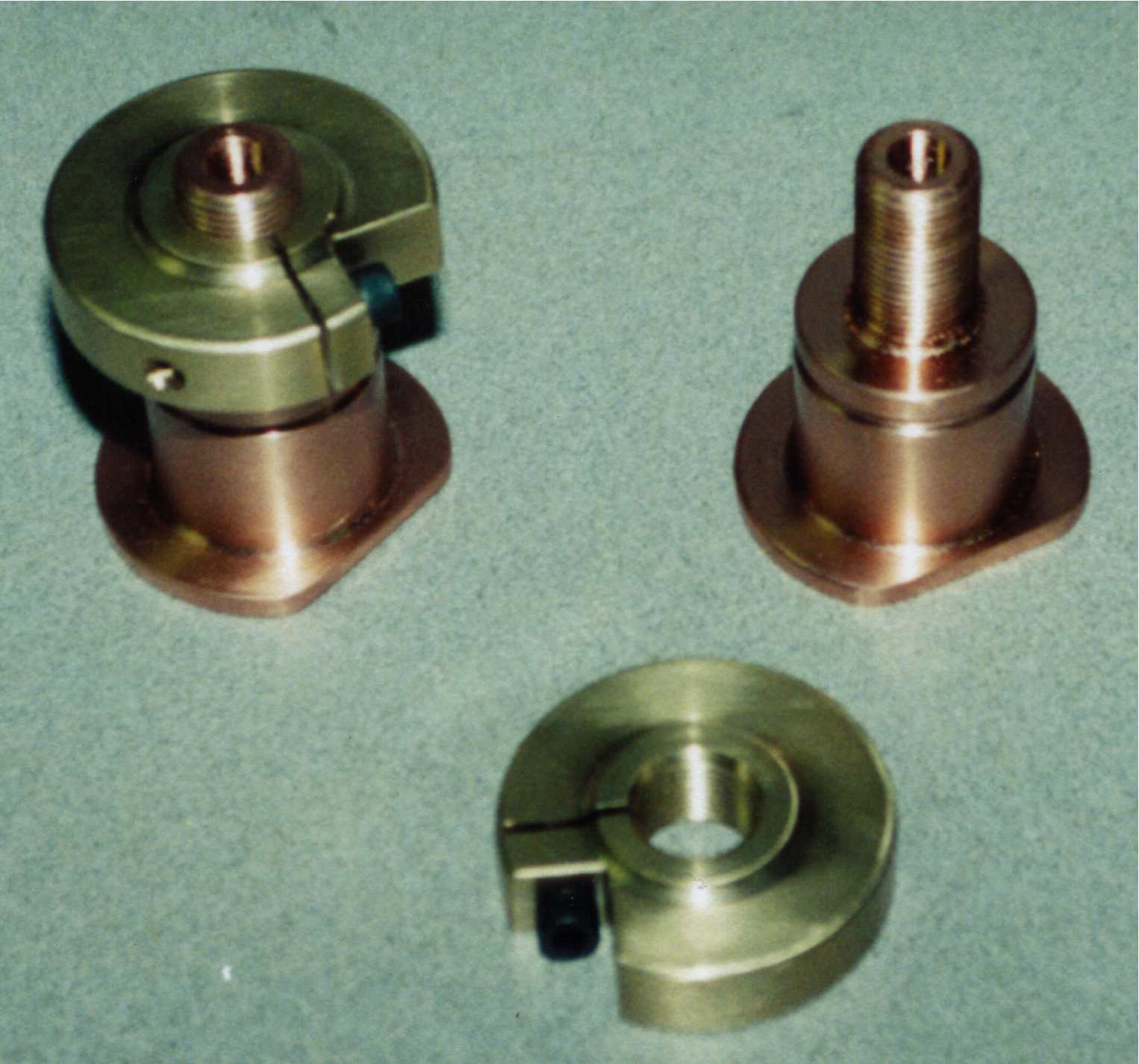

“We can and will do anything for a customer!” Recently, a customer came to us after exhausting other far-flung places to have a complicated part broke from a special high-strength, very low elongation material. The Amada tooling engineers described it as “utterly impossible to complete.” We offered to work through the issue alongside the customer if they wished. They did. Over the next few days, FABCO developed alternative methods to the special part and produced samples for lab testing. FABCO produced almost 400 parts for field testing. This allowed a multi-million dollar product application to proceed. We take on challenges, and when faced with difficult tasks, innovation is second nature to the FABCO team!

FABCO is best known for the size and scope of the work we produce. In our 25 years of serving the industry, we filled the need for a high-quality large fabrication facility to handle the heavy, precise machining desired. We have assembled a qualified team and facility to support machine work that is unequaled in this region. Constantly aware of the needs of our customers, we strive to install capacity to allow them access to local tools to meet these needs.

FABCO Machine Corp provides the highest quality manufacturing and machining services in Northeast Arkansas since 1994. We continue to grow thanks to our customers’ support and the demands of an ever-changing manufacturing world. Now with 100,000 square feet of manufacturing floor space and multiple high bays, we have the capacity for almost any project. We continue to upgrade equipment, as well as the skills of our machinists and fabricators. Our special emphasis is currently focusing on developing the area's largest and heaviest fabrication facility. Our Engineering department uses state-of-the-art CAD/CAM software and can help with initial design, analysis, and build management. We develop 3D models in-house for our CNC programs for our 54 CNC machines and can operate directly from your models.

FABCO Machine Corp provides the highest quality manufacturing and machining services in Northeast Arkansas since 1994. We continue to grow thanks to our customers’ support and the demands of an ever-changing manufacturing world. Now with 100,000 square feet of manufacturing floor space and multiple high bays, we have the capacity for almost any project. We continue to upgrade equipment, as well as the skills of our machinists and fabricators. Our special emphasis is currently focusing on developing the area's largest and heaviest fabrication facility. Our Engineering department uses state-of-the-art CAD/CAM software and can help with initial design, analysis, and build management. We develop 3D models in-house for our CNC programs for our 54 CNC machines and can operate directly from your models.

Our Core Values: Honesty, Integrity and Teamwork are shared across the organization. Our focus is Excellence and Innovation in all we do.

The Mission of FABCO Machine & Engineering is to continue fulfilling our customer needs with trouble-free, superior quality machined and fabricated products and services. Our customers appreciate our ability to provide unique, rare and valuable products. These products and services, in turn, enable our customers to enhance their processes. A close customer relationship has always been the cornerstone of our business with relationships that hinge on trust and a handshake.

The products we supply are of high quality and have attributes that enable customers to efficiently carry out their business functions. We fulfill our mission on-time by using progressive technology, and evolving ways to improve our processes. Our pursuit of excellence is driven by the principles of our Quality Management System.

We provide on-time delivery of purchased products and fast turn-around of emergency repairs, thereby reducing customer downtime and the associated costs.

As one of the few providers of Meta-Lax® vibratory stress relief in Arkansas, FABCO is your best choice for stress relief for precision metal parts. Our welding technicians are AWS-certified and have years of experience with machining stress relief on complicated and large parts. We use Meta-Lax® for post-welding stress relief because it offers the combination of value, efficiency and innovation our clients desire.

FABCO has several portable machines in our arsenal to support machining at your facility. These were specially designed to recondition existing roll centers that have been worn and damaged over time thus restoring the accuracy of the centers up to 24” diameter. They can be used for placing new center holes, as well as other end operations.